teardown

Two teardowns were conducted to analyze the internals of a jigsaw and to help better understand the manufacturing elements that have been implemented to reduce cost.

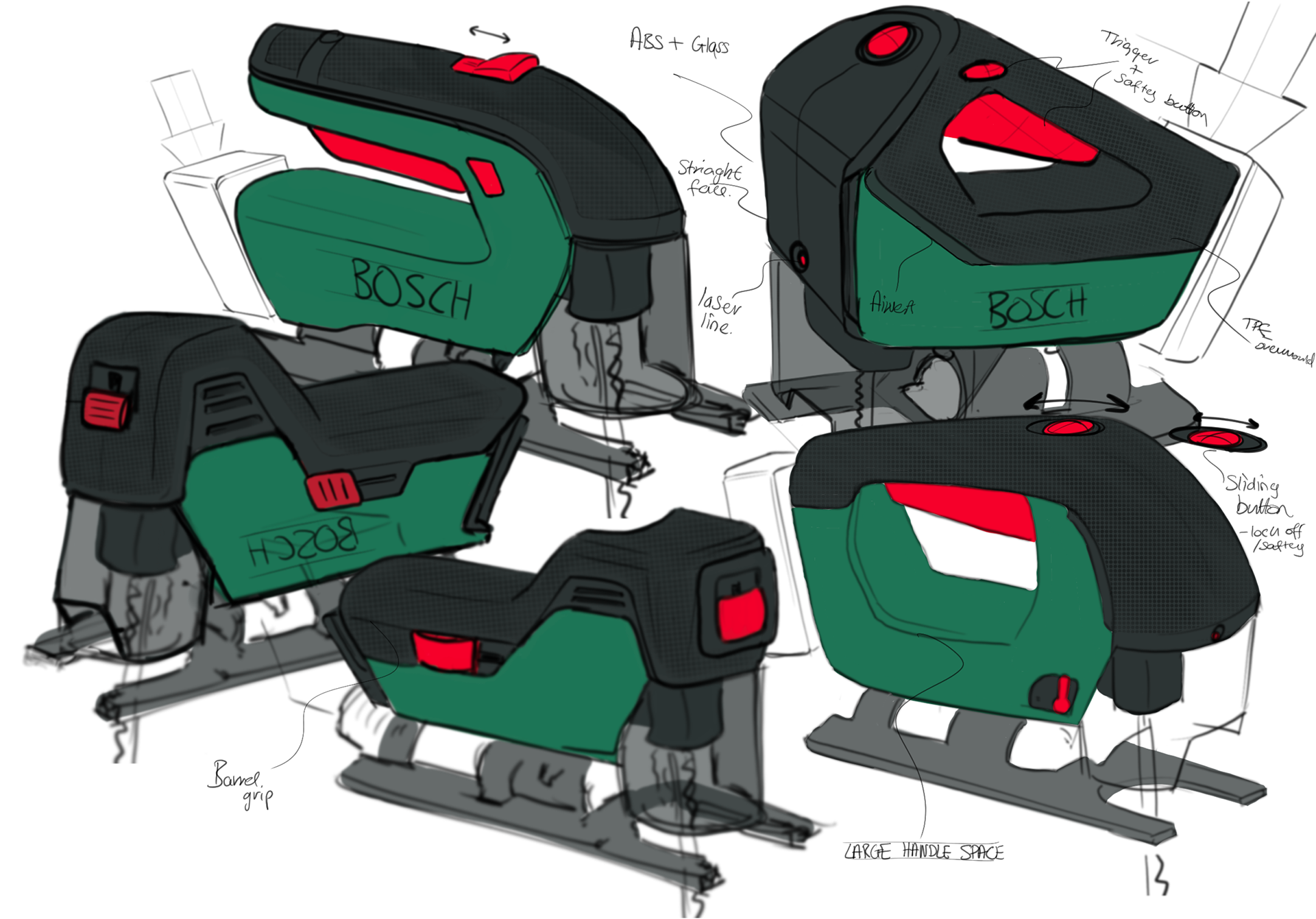

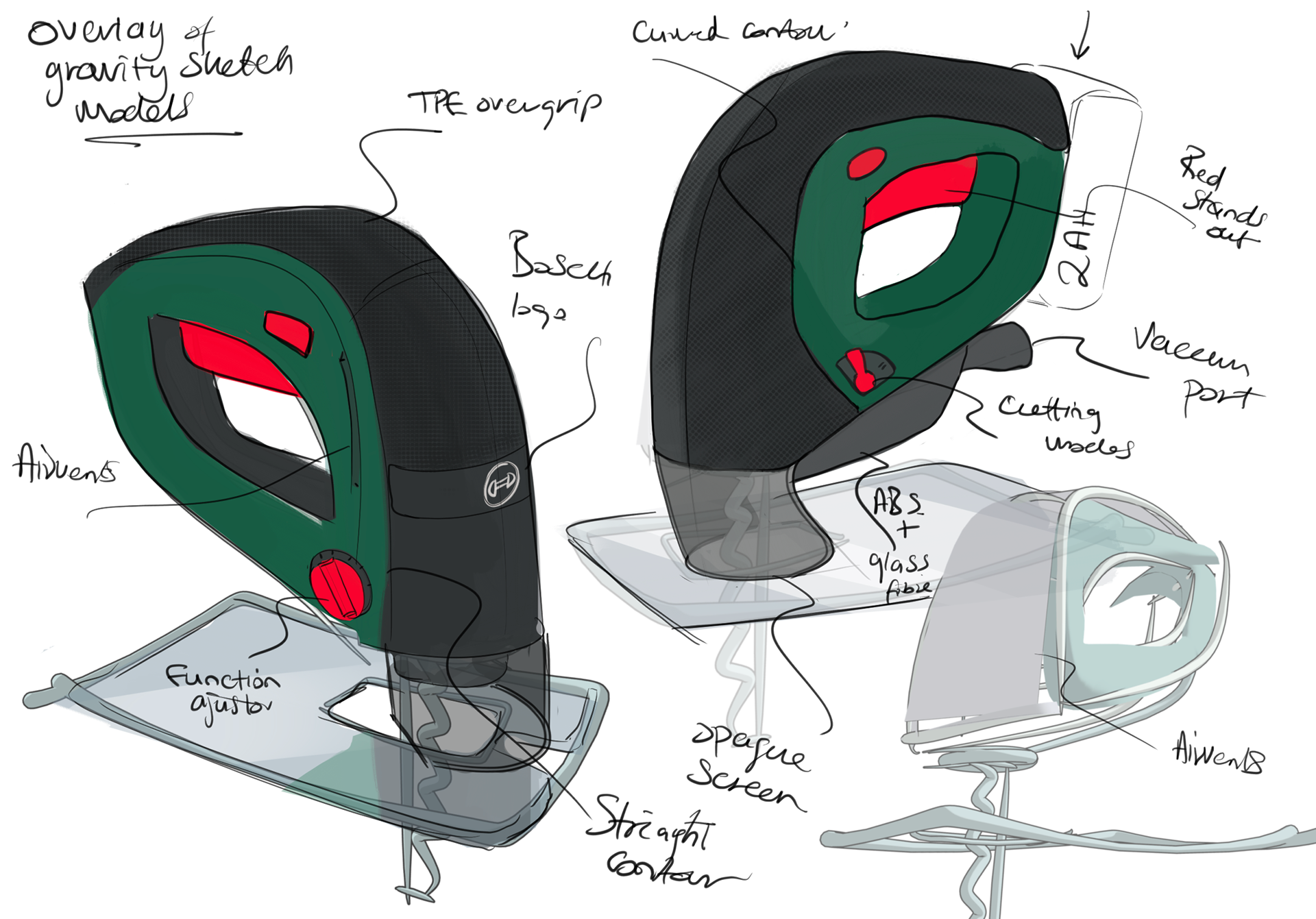

ideation

Around a week was spent ideating concepts and creating low-fidelity models to explore ideas and scale. These would be used in the studio to help convey my ideas to other students and tutors.

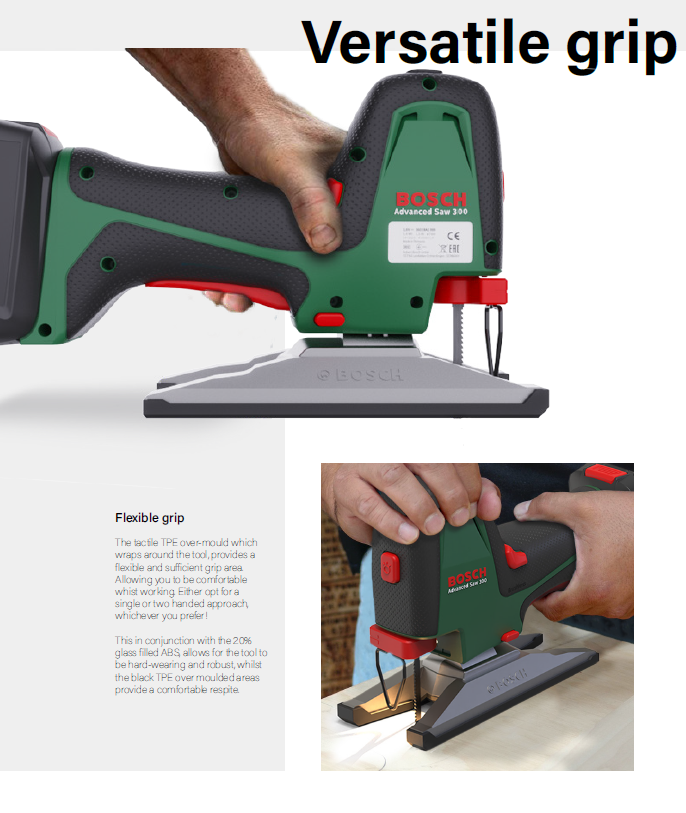

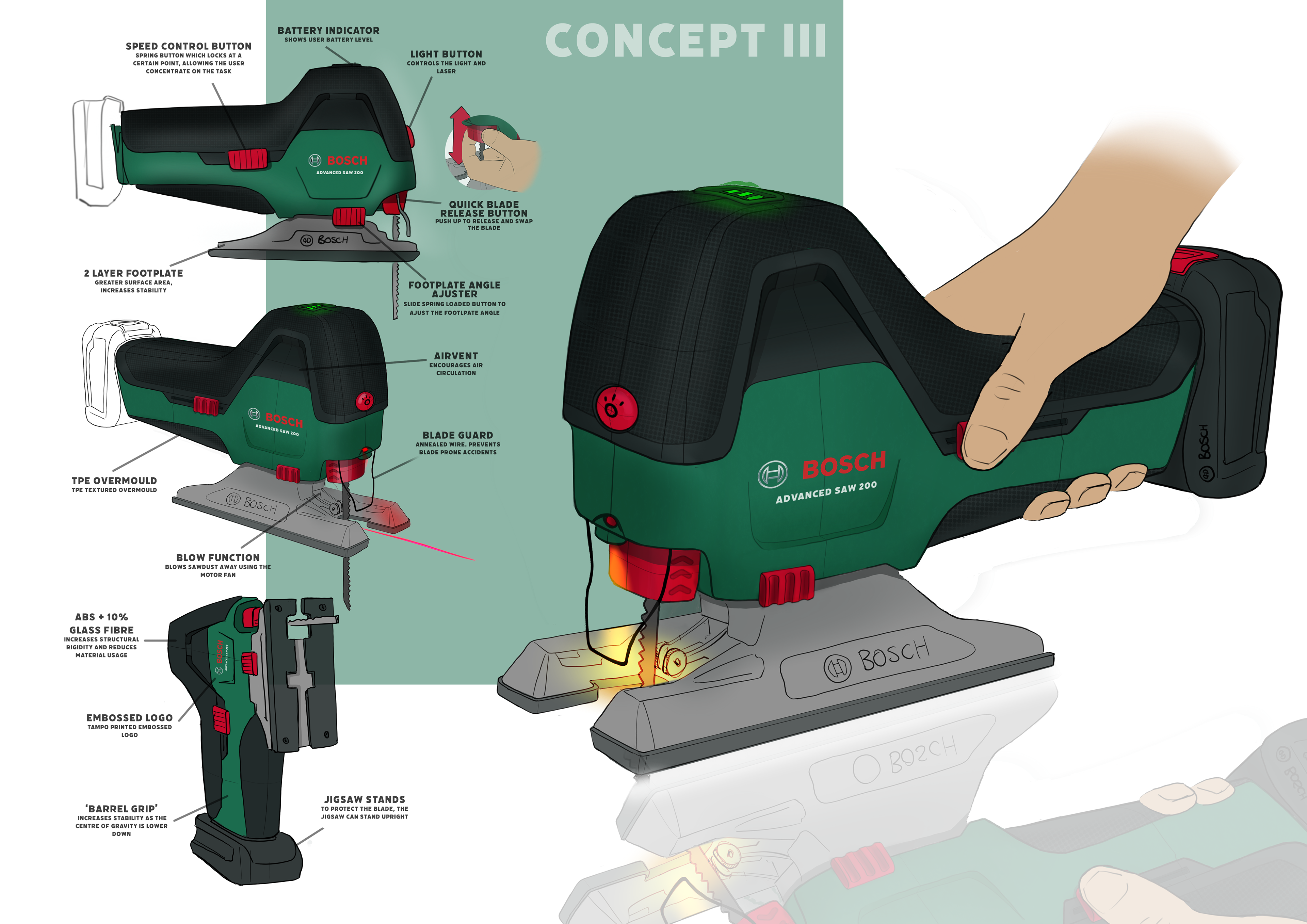

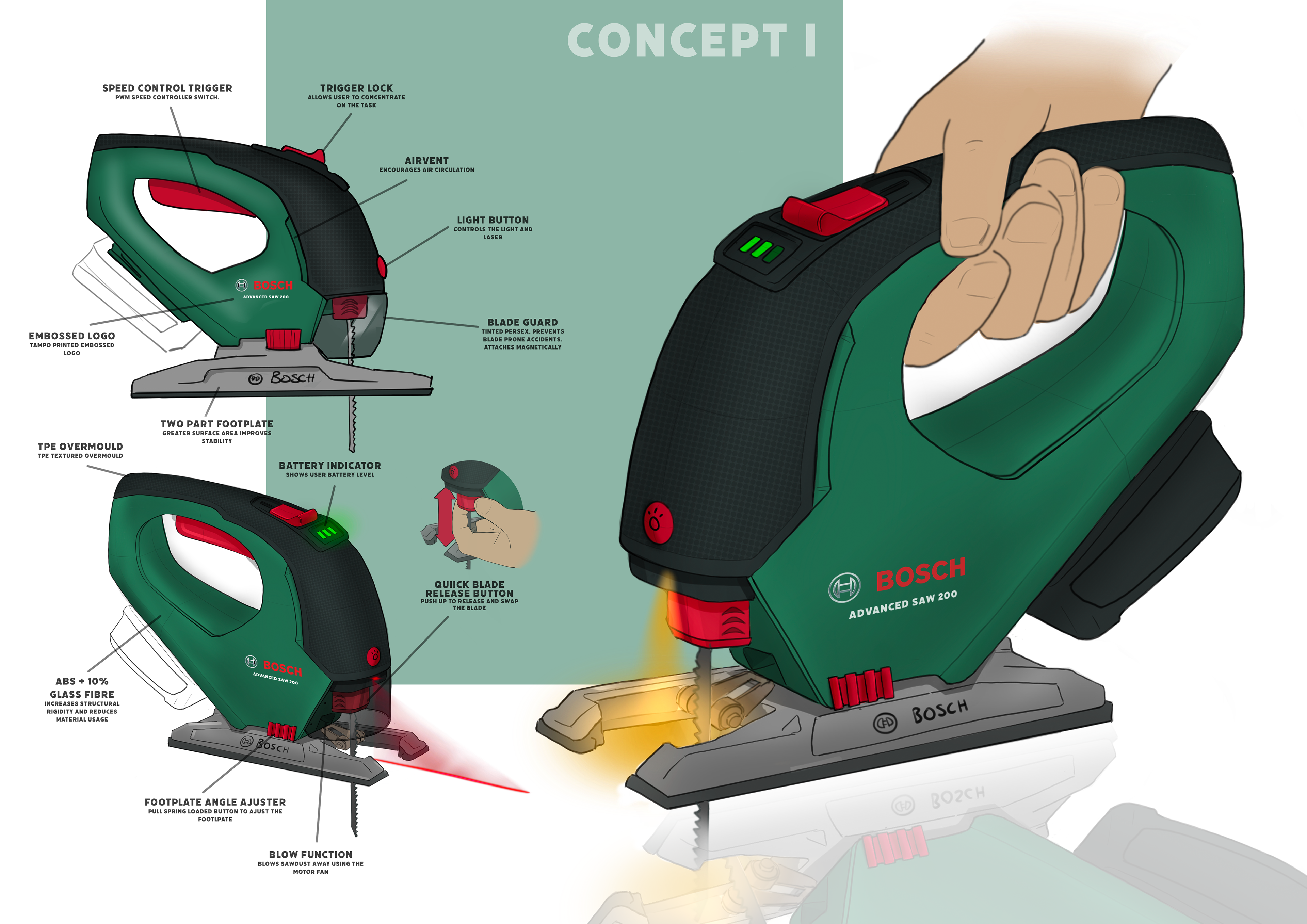

concept boards

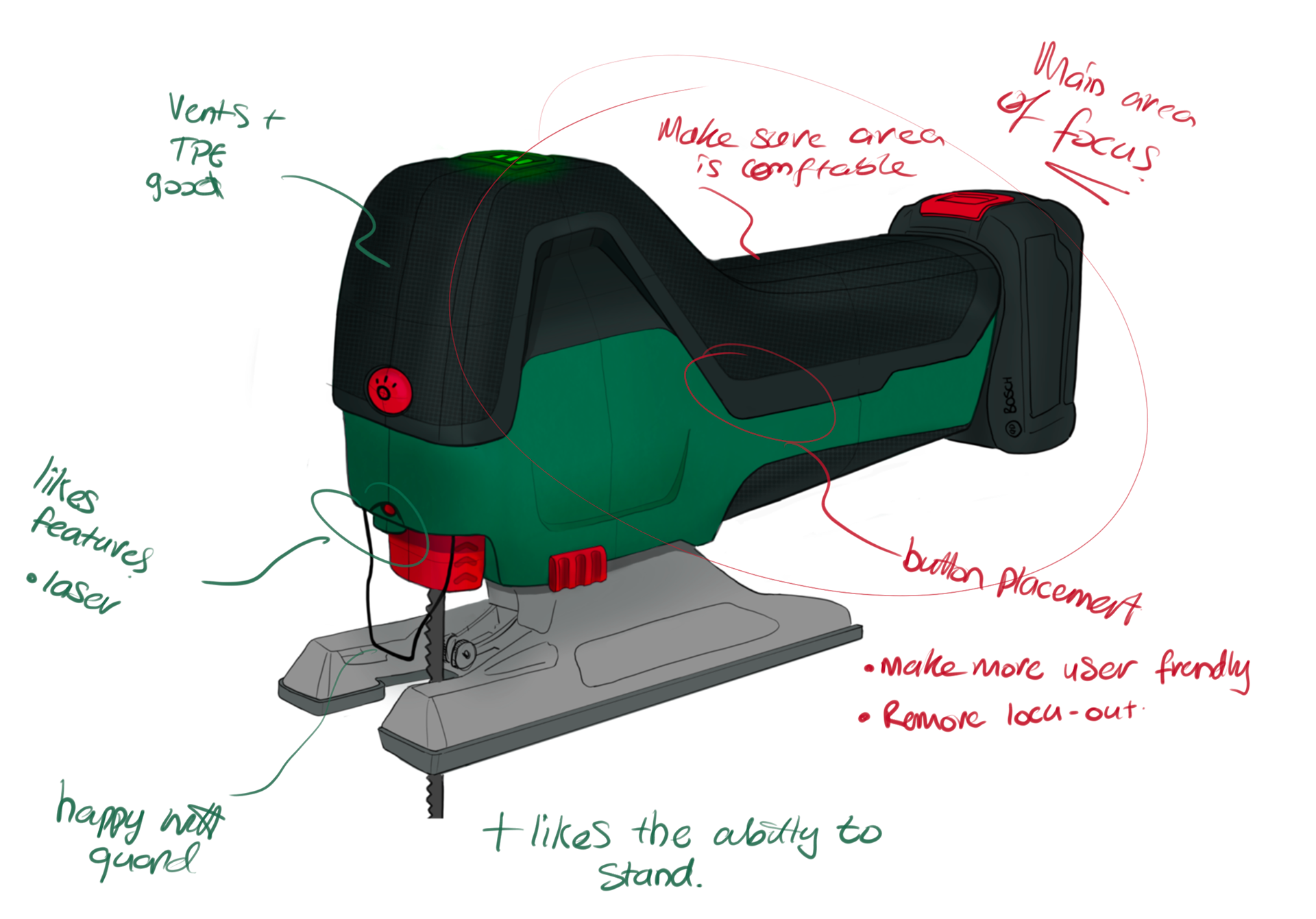

These boards show the proposed design solutions and were presented to the client. They summarise intended features, materials, and interactive elements.

Upon concluding the presentation, the client expressed their preference and changes and areas to look into for development.

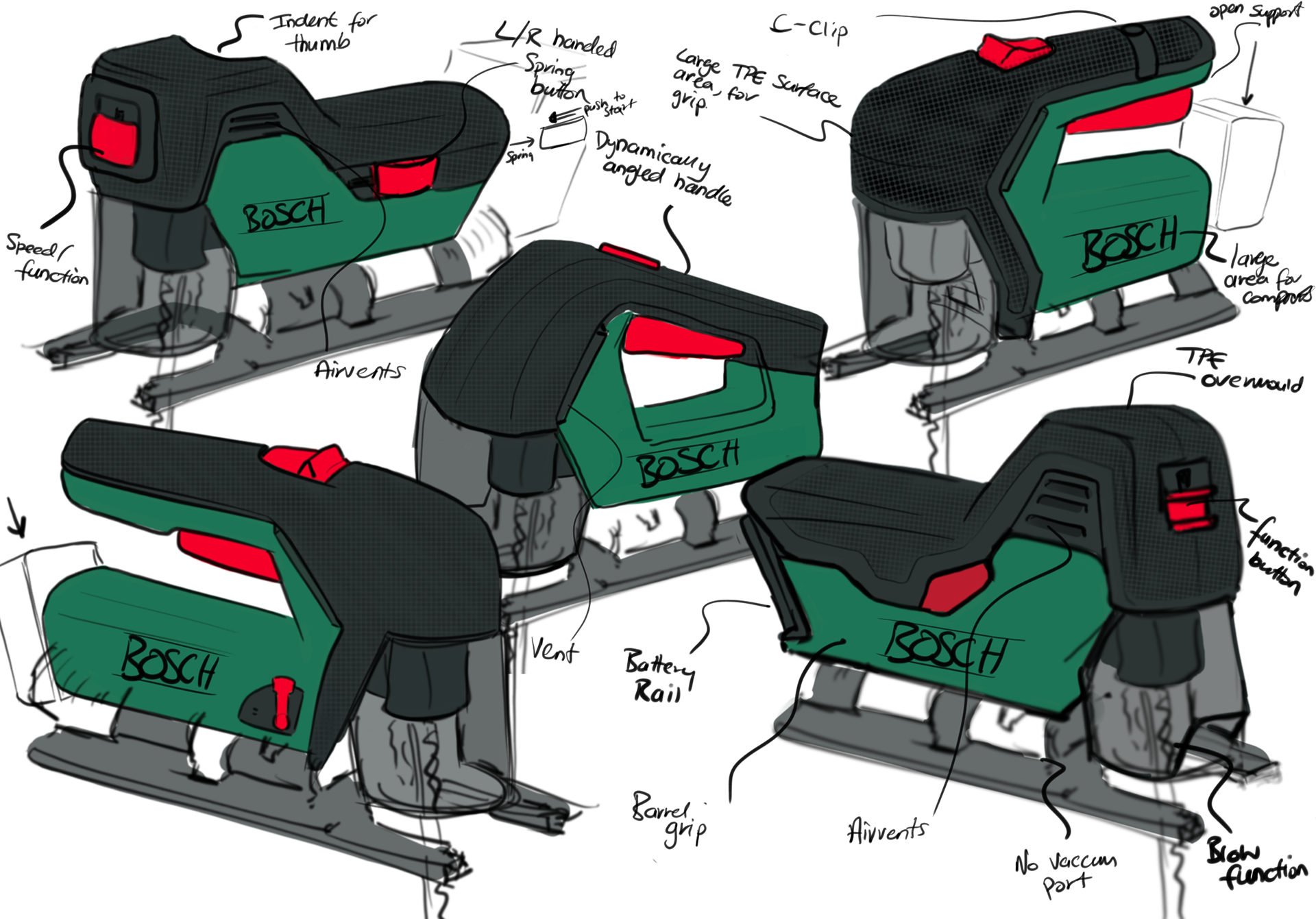

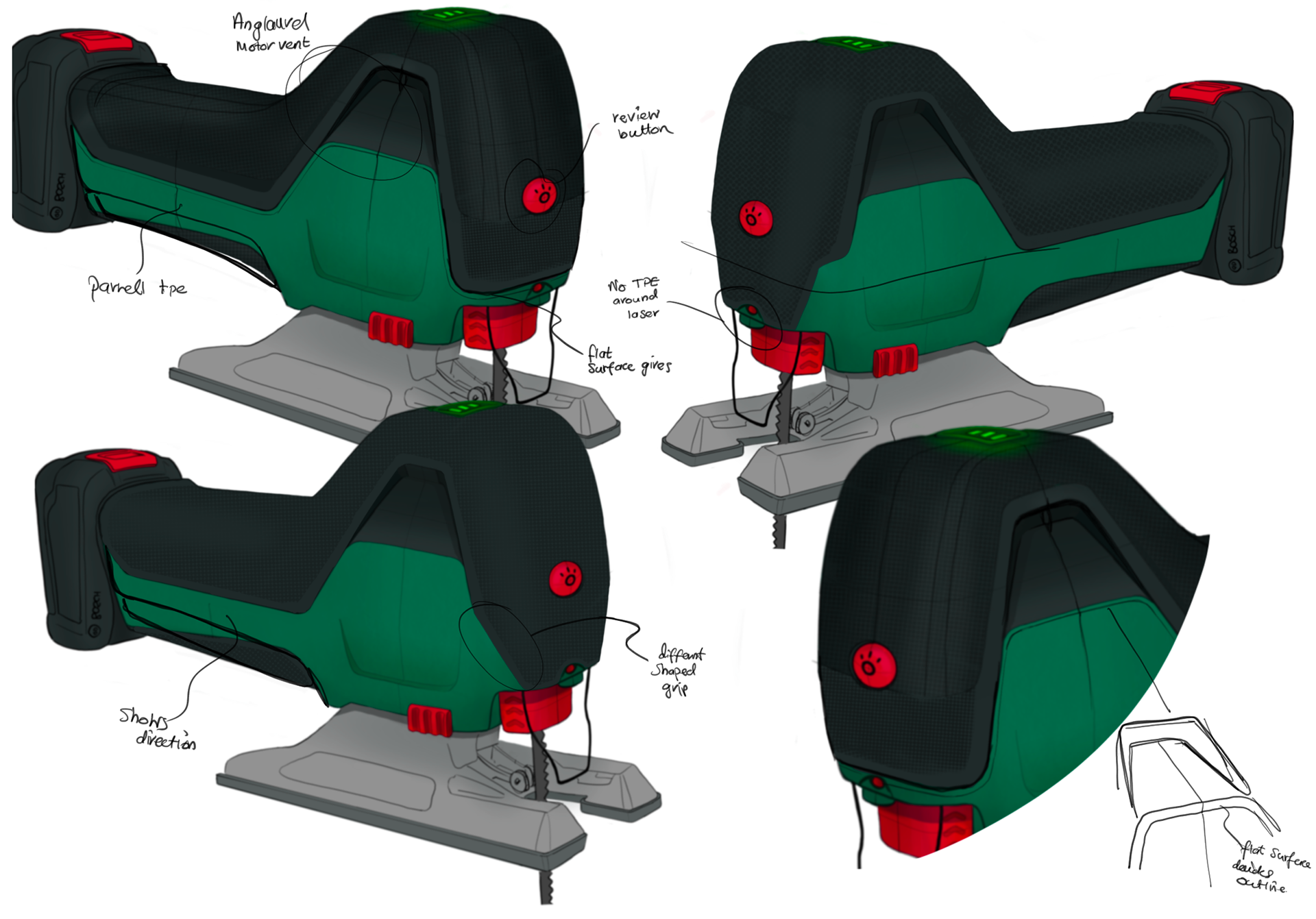

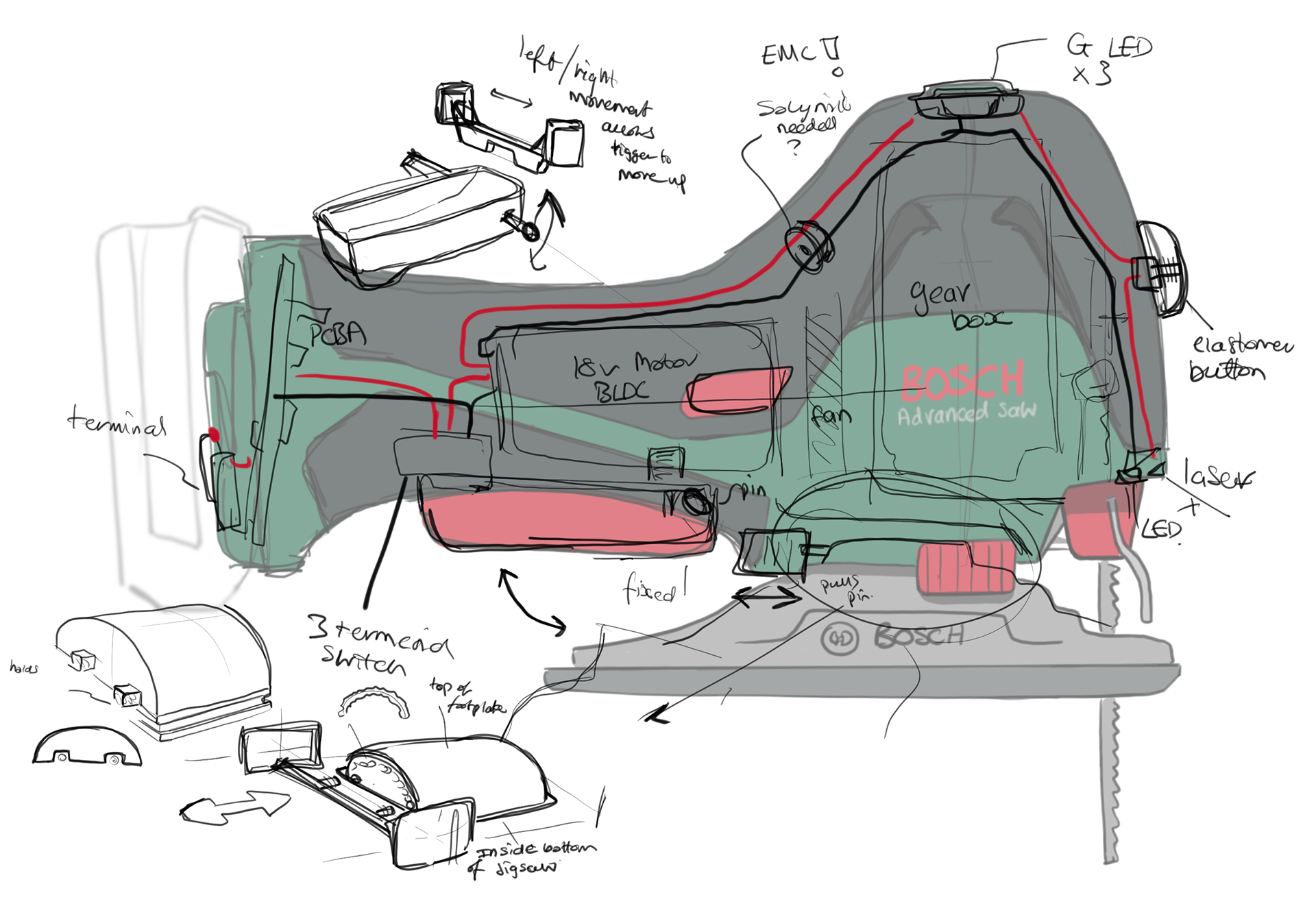

developmental sketches

To the left are just a handful of images showing a glimpse into the thought process to develop the Jigsaw from the concept boards to the final result.

developmental models

A total of 29 models were produced, across several weeks, these proved invaluable to test ergonomics, button location, and overall scale and aesthetic. Shown on the right, is just a handful of prototypes.

CAD

The product was produced using surfacing to ensure high-quality surfaces. The product was also created around the internals, ensuring a feasible product was produced.

solution

This is my solution to BOSCH's market share loss, a revamped 18V barrel grip jigsaw. Featuring a double safety trigger mechanism, a laser, and a torch. With an integrated blade guard.

presentation model

To the left is the presentation model, which was produced to show the client before going to the manufacturer. All interactive elements can be used and the internal components are also included to mimic weight.

Models are invaluable for development and a total of 29 models were produced across the several weeks of development.

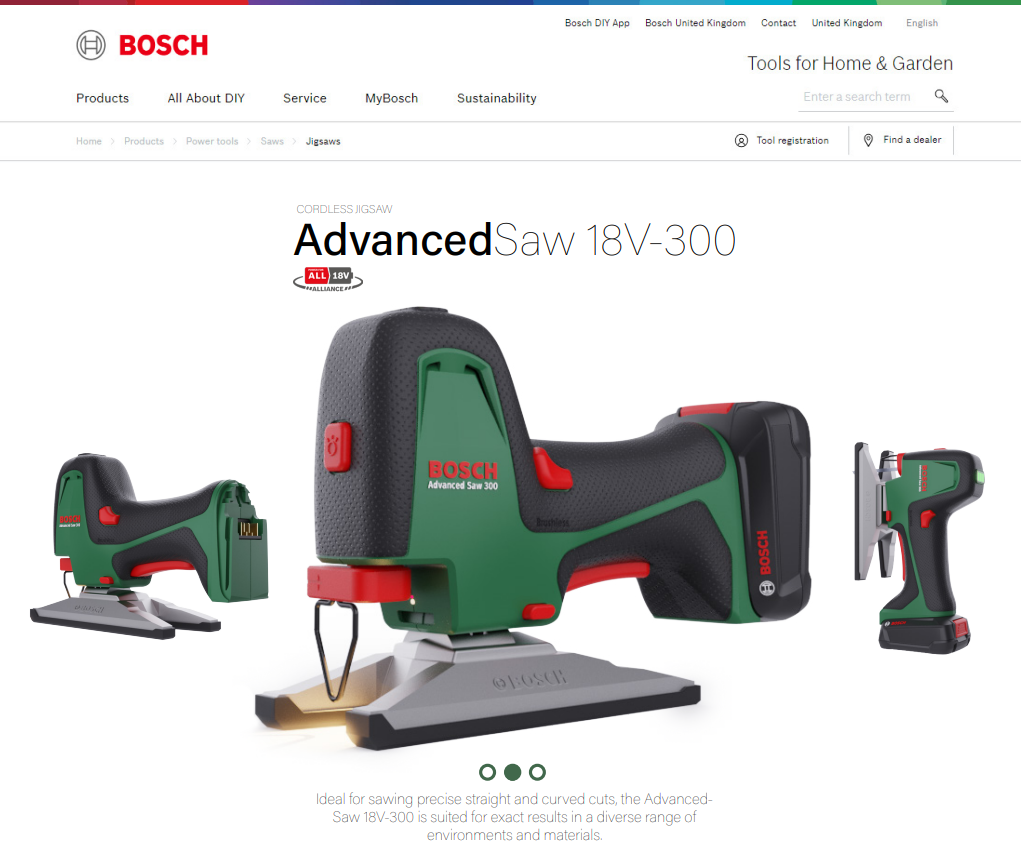

website mock-up

An interactive mock-up website was produced to show how the product might be displayed on a website. It shows the features, and how the interactive elements have been intended to be used as well as technical information such as runtime, etc.