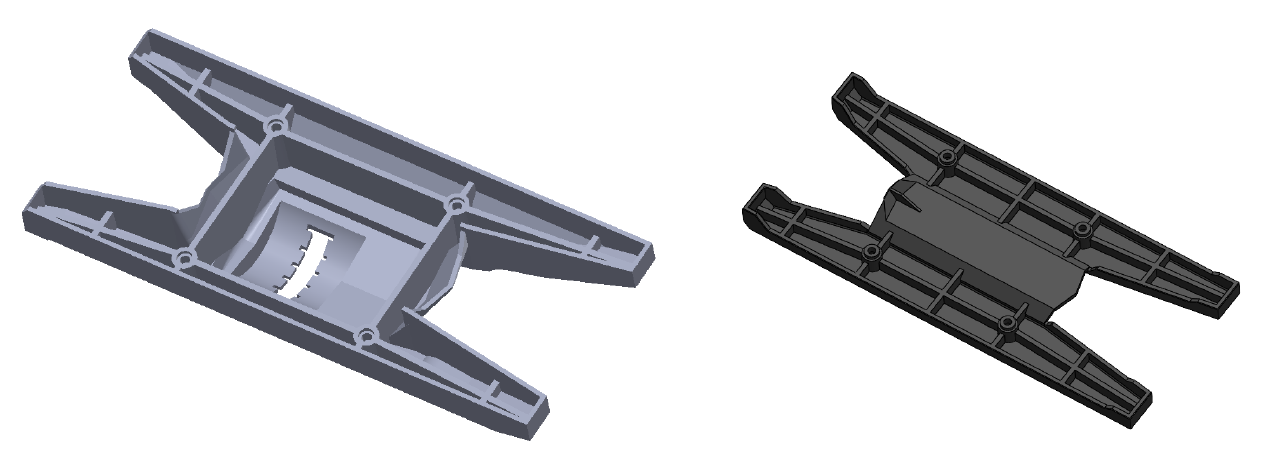

The following model has been produced with surfaces. Surfaces produce a much more coherent surface flow, ensuring the product is seamless. The example on the right is the rear of the BOSCH 18V Jigsaw.

Draft analysis

One of the quickest yet arguably one of the most important analysis techniques is the draft analysis. This analyses your model, informing you of any undercuts and any areas requiring draft input. Essentially for molded components.

Flow simulator

During the development process, a wealth of simulations are conducted to ensure the design's suitability. One example, shown on the left, is the flow simulator. As this part will be injection molded it is crucial to understand how the polymer will flow when injected.

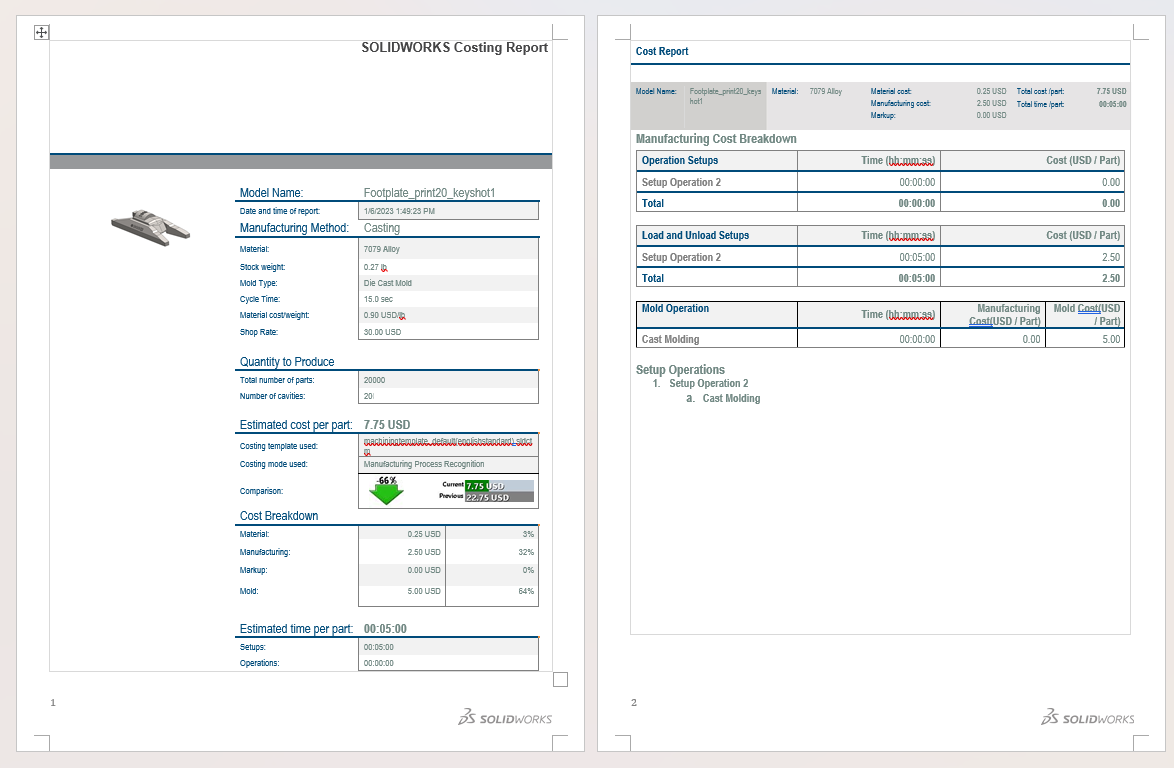

Costings calculator

The cost of the parts is an imperative step in ensuring the product is price competitive. Not only does it provide the client with a good estimate of predicted costs but it shows where costs can be reduced before committing to tooling.

The example on the left is the costing simulator for the Metal injection molded part [MIM], for the upper section of the footplate. Made from an aluminum alloy, with a manufacturing quantity of 5000, it predicts the price per part.